by Juanita | May 27, 2021 | 50th anniversary, Ava Lee's History Corner, George's Furniture

George realized his natural gift and talent for making quality wood products and wanted to spread the word. The challenge with spreading the word about quality of hand-crafted products is finding customers who appreciate handcrafted items.

Craft shows

George first displayed his wood items at Springs Festival, Springs, PA. He skillfully created live edge furniture such as stools, benches, tables, and bookends. Thin, woven wood-strip baskets and lamp shades characterized his unique, woodworking styles. Throughout the show day,  George engraved custom plaques ready in one hour. Other larger wood items like rockers, dry sinks, trestle table and benches were available for purchase. Customers also used the furniture to explore the different furniture style options for placing custom orders. For many years, the order placed at the craft show supplied work for the next 12 months. George not only went to Springs festival but also displayed his crafts at the Dutch Family Festival in Lancaster, PA during the summer tourist season.

George engraved custom plaques ready in one hour. Other larger wood items like rockers, dry sinks, trestle table and benches were available for purchase. Customers also used the furniture to explore the different furniture style options for placing custom orders. For many years, the order placed at the craft show supplied work for the next 12 months. George not only went to Springs festival but also displayed his crafts at the Dutch Family Festival in Lancaster, PA during the summer tourist season.

First Showroom

In 1973, he rented a small showroom at 4 Center Square, Elizabethtown, PA. Later that winter he moved his furniture store to 20 S. Market Street, Elizabethtown, where he sold furniture for thirteen years. This furniture store was quite small but allowed customers to see the quality of craftsmanship made by George and his craftsmen. On Friday and Saturdays, he also had a stand at Meadowbrook Farmer’s Market, Leola, PA. George purchased a 12-acre farm where he moved his wood working shop into the dairy barn.

Showroom and wood shop tours

One added benefit our customers enjoy is touring the wood shop. George moved the showroom to the same location as the wood shop. Allowing customer to view the furniture manufacturing shows everyone the time and attention to detail given to each piece of furniture. The larger showrooms  present a visual display of completed furniture. Larger furniture-dining room sets, bedroom suites, living room tables, entertainment centers are displayed.

present a visual display of completed furniture. Larger furniture-dining room sets, bedroom suites, living room tables, entertainment centers are displayed.

Visit Today

Our two large showrooms are located 9 Reichs Church Road, Marietta, PA, Monday through Saturday. The wood-shop tour exhibits the manufacturing process from raw lumber to finished furniture. Take a trip to our location and enjoy the quality furniture and talk to our design team about a new piece of custom-made furniture. We also display our furniture at craftshows in the Eastern United States. Check our website for updated schedule.

by Juanita | May 3, 2021 | Coffee End Table, customer experience, Customization, Events, George's Furniture, Hutch

George’s Difference – Viewing Your Own Handcrafted Furniture

The next time you visit Lancaster, PA we want to give you a tour of our shop where each piece of our solid wood furniture is handcrafted & custom made. Yes, it is true! We love bringing guests on a tour of our wood-working shop. Quite honestly, that is what makes us different from nearly any other furniture shop you can think of.

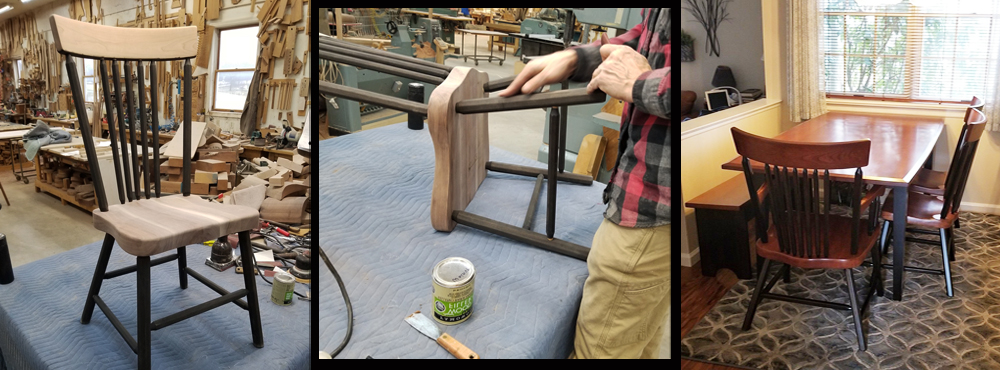

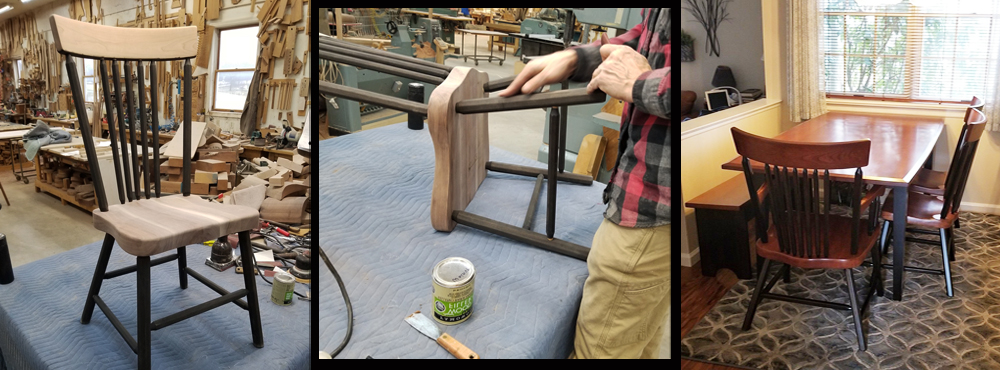

Of course, it is not just a tour of some automated wood shop. You see our craftsmen at work, literally drilling, planing, and staining with the tools in their hands to produce your perfect handcrafted solid wood furniture. Actually, we invite not only our guests but any customer with any order in progress to schedule a time to visit & watch their furniture crafted by hand right in front of their very eyes. That was how Tom & Karen found us!

See furniture order handcrafted

“My wife and I had been furniture shopping for over a year and decided it was time to buy. While my wife was getting ready, I decided to make one last internet search for Lancaster County furniture stores. I was positive that we had already visited every furniture store so I was not optimistic about finding something new. George’s Furniture appeared on a list of stores we had previously visited, some of them multiple times. They were located near Maytown so I clicked on their website.” -Tom

The beauty of creating custom handmade furniture is that we can support your vision in a way that works for you, instead of just selling you assembly line, machine-made furniture.

Perhaps you need a dining table that is large enough to host all your children & grandchildren for a holiday meal. Maybe you are looking for a bedroom set that can become a family heirloom & add to the beauty of your home. In the professional setting, we even love designing executive desks & conference tables. (Did you know we even designed a conference table for the Pentagon?)

Beginning the handcrafted furniture process

“We were met by Anthony upon our arrival. After explaining what we were looking for, he expertly guided us through all the options. When ordering custom made furniture there are lots of decisions to make. After several hours our order was finalized.” -Tom

Tom and Karen worked with our designers to create the perfect dining set to meet their specific needs and interests. They also scheduled an appointment to see their furniture in process.

As we walked them through the tour, they saw the chairs ready for assembly. The artisan carefully placed glue into the precisely angled holes drilled into the seat for the chair legs. Tom and Karen observed the chair leveling process to make sure the chair would sit level in their home.

“I didn’t realize that so much work goes into making furniture.” — Tom

The finished table waited in the completed area. In the wood shop, they could see the other pieces of their set in progress too. A bench sat ready for assembly. The glued together coffee table wood top was ready for its next step of shaping and edge routing. The stained pantry waited for the final clear water-resistant coat of catalyzed conversion varnish.

Assembly lines vs handcrafted

Several minutes into the tour, Tom asked about the difference between George’s furniture process and other furniture manufacturing.

He referred to the cost and time difference of mass production assembly lines. We know many of our customers & guests wonder the same thing.

He referred to the cost and time difference of mass production assembly lines. We know many of our customers & guests wonder the same thing.

To be quite honest, mass production uses automated production lines and large sheets of plywood and particleboard in the construction. Since their focus is often on quantity over quality, they spend little time on matching grain or on preparing the wood well for assembly. We take the extra time of planing, cutting, and gluing the solid wood pieces together. That is what makes our process so different.

The path to quality

Handcrafted custom furniture made at George’s shop displays the careful attention to the wood grain, design, durability, and strength of the construction. Can I walk you through our complete process?

- Each artisan selects properly dried solid wood boards & cuts them to length. They use a jointer in their preparation process to make the boards flat, square & easy to assemble together (You can find out more about how jointers work here.) A thickness planer is also an essential part of this process to prepare the board & ensure that it is the same thickness all the way around the board. (The thickness planer is explained more here.)

- The furniture is ready for assembly after construction of all the individual parts. All those individual parts often include legs, skirts, tops, sides, solid wood drawers (fronts, sides, bottom), raised panel doors, rungs, seats, chair top, tongue-groove backing, etc.

- Next, they stain it and apply a clear coat of finish. The artisan signs and dates their finished piece before an all-over light sanding and final application of water-resistant clear coat of spray-top to bottom, inside and out. We actually asked our previous customers if they can still see the signature on their piece & these are the photos they shared with us.

- The final step in assembly is installing the hardware such as knobs & handles on drawers, adding in the table slides (our extension table is one of our most popular products actually!), and completing the tongue and groove backing.

- Last stop is the storage area where the finished product waits for the completion of the other pieces in the order. For example, maybe you have ordered a full dining table & chairs set like many of our other customers. Maybe you even ordered a bedroom suite of a bed, night stand & chest of drawers. This final waiting area is where we collect all pieces of an order before we deliver the complete set to the customer’s house.

Time to enjoy your gorgeous handcrafted furniture

“Our furniture was recently delivered and we are very happy with all the pieces. They are gorgeous and exactly as we ordered. The entire process from beginning to end was very pleasant and trouble free. We visited the shop and saw several of our pieces while in production. In closing, my wife and I would like to sincerely thank everyone at George’s Furniture.” – Tom & Karen

This is what makes us different from any other furniture shop you have visited. You set the vision & we are happy to share our catalog of creations if you need inspiration. Then you can tour our shop to watch our master woodworkers bring your vision to life. Finally you get to enjoy quality, handcrafted furniture that will last your family for decades.

To help you start this process to high quality, handcrafted furniture, we created this handy checklist to spot high-quality furniture. Download the checklist here so you know what to avoid in your furniture shopping. Then call us when you are ready to design your own custom, handcrafted piece.

by Juanita | Sep 26, 2020 | Ava Lee's History Corner, customer experience, George's Furniture, Hutch

It all started when Bob and Rachel visited their friend’s home. They noticed beautiful furniture skillfully placed around the living space. Furniture of this quality is hard to find. However, after years of searching, they finally found it right in their friends home. When questioned where the beautiful furniture came from, their friends ecstatically shared the journey that ended at George’s Furniture, Marietta, PA.

Journey begins

Bob had a remodeling project scheduled. After four years the new addition neared completion. Subsequently, they planned a trip to Lancaster County. A beautiful drive from Vermont to Pennsylvania brought Bob and Rachel to George’s Furniture’s showrooms and the wood working shop. During a wood shop tour, Bob and Rachel saw the craftsmen skillfully creating quality heirlooms. Finally they knew this was the birthplace of their new dining room furniture.

Built your way

They met with Anthony and started the journey of designing their desired dining space. After the order was placed and the waiting began. As an added benefit, Anthony sent several pictures of their furniture progression through the wood shop in the different build stages.

Bob quotes,

“Anthony did a fantastic job of working with us patiently while we determined what we wanted even to the point of thinking outside the box of choices to design the legs of the hall tree to match the table legs.”

Careful Delivery

Upon completion, the delivery personnel carefully blanket wrapped the furniture and skillfully placed it in the van for its trip to Vermont. A warm and excited reception greeted Chris and Juanita after a long 8 hour trip in the delivery van. Several neighbors eagerly waited, ready with open arms to transport the table, chairs, table leaf storage, large hutch, buffet, hall tree and 2 non-tip rocking chairs into the house.

“We knew the kind of quality we could expect but when the dining room furniture arrived, we were blown away by the quality of each piece individually and how the whole room of furniture fit together.”

Quality on Display

Rachel’s excitement exploded as she shared their journey discovering George’s Furniture. She looks forward to gathering everyone around the same table in their newly remodeled dining room. Bob and Rachel joined the family of George’s satisfied customer that can’t contain their excitement and love for their furniture. Join the family and create you next new piece of furniture. Come and see where your furniture is built or contact us to started the journey.

by Juanita | Nov 8, 2019 | Ava Lee's History Corner, Office, Tables

Pentagon commissions expanding conference table

“West Donegal woodworkers crafts table for Pentagon.” Lancaster News Paper headlines announced a local family-owned business received a commission, an expanding conference table, from the Department of Defense. See complete story.

Quote to Completion

It all started with a quote. Tipped off by a current customer/employee, the Department of Defense commissioned George’s Furniture to design an expanding conference table. The table measures 8 ft in length however, it expands to 12 feet, allowing for the flexibility in meeting sizes. The Pentagon accepted the and the fun commenced. Assigned to a skilled craftsman, the conference table continued its journey to completion. Lancaster News papers heard the news. A Lancaster County business making a table for the United States government! They were ecstatic. A reporter was quickly assigned, however, the photographer barely snapped enough pictures before the craftsman finished building the table.

Unique Delivery

Meanwhile, delivery preparations were finalized, clearances submitted and specific instructions confirmed for transporting the table to its final Pentagon office location. At the security gate, government employees carried the heavy oak conference table into the complex.

Grand Tour

As a result of a department meeting going overtime, the delivery which Chris and Anthony thought would be short, turned into a 3 hour ordeal. During a three-hour grand escorted tour around the Pentagon, they explored the many hallway displays and the inventory room that keeps track of everything from toilet paper to combat tanks!

Back to work

Once the meeting finished, Chris and Anthony assembled the conference table. Firstly, the men secured the legs and the hooked the cabling into the two receiver boxes. Secondly, they placed the four table leaves into their storage cabinet to quietly wait for the next large meeting. Lastly, they gave instructions about how to properly operate the table.

Currently the table’s handcrafted strength and natural grain quality shines for everyone assembled. Gather around George’s tables for your next family or business gathering. Contact us.

by Juanita | Apr 19, 2019 | Customization, George's Furniture

Amish Communities

Ohio, Pennsylvania, and Indiana are home to the largest Amish Communities in the United States. The Amish lifestyle consists of plain clothes, horse and buggy, no electricity, one-room schoolhouses, and farming. Over the years they developed a reputation for their quality quilts, furniture, baked goods, and produce. In fact, in 2015, about 8.34 million visitors to Lancaster County directly spent $1.97 billion, creating a total tourism impact of $2.64 billion in the county.

Quality Compromised

Over time, marketing replaced craftsmanship. While a few Amish craftsmen are still producing quality furniture, many stores market Amish furniture devoid of the quality buyers expect. As the perception of the quality Amish furniture increases, the natural result is an increase in demand. This increase brought new systems and processes which dropped the quality of the product. They compromised when materials such as cheaper stains, protective coatings, glue, or hardware. They left the old process of construction behind while newer methods of cheap assembly take over. These newer methods, which use assembly lines and computerized machines, compromise excellence for the convenience of efficiency. Consequently, the quality of hardwood furniture is lost along with the buyers ability to customize their product.

Furniture Experts

Furniture Experts

Furniture experts pinpoint pieces displaying true quality, handmade Amish furniture. The untrained eye, however, sees little or no distinction. While Amish craftsmen are talented, rarely is the resulting piece considered by furniture experts as constructed by a Master Craftsman. Why does this matter? Furniture crafted by a Master Craftsman ultimately become heirlooms.

Master Craftsmen

Heirlooms are pieces constructed to withstand the test of time and passed down to the next generation.  Furniture designed, crafted, and assembled by master craftsmen endure the normal wear and tear of daily life. While George’s craftsmen are not Amish furniture makers, we are Master Craftsmen. George’s master craftsmen build each piece to suit the needs of the buyer now and in the future. Forever cherished assets.

Furniture designed, crafted, and assembled by master craftsmen endure the normal wear and tear of daily life. While George’s craftsmen are not Amish furniture makers, we are Master Craftsmen. George’s master craftsmen build each piece to suit the needs of the buyer now and in the future. Forever cherished assets.

George’s Difference

At George’s Furniture, one craftsman uniquely crafted each piece – signed and dated. 100% Pennsylvania hardwood construction—no plywood here! Each item is built-to-order, custom made to your specifications. Visit our showrooms and see the furniture manufacturing! Time-tested construction for over 50 years…that’s the George’s difference.

At George’s Furniture, one craftsman uniquely crafted each piece – signed and dated. 100% Pennsylvania hardwood construction—no plywood here! Each item is built-to-order, custom made to your specifications. Visit our showrooms and see the furniture manufacturing! Time-tested construction for over 50 years…that’s the George’s difference.

George engraved custom plaques ready in one hour. Other larger wood items like rockers, dry sinks, trestle table and benches were available for purchase. Customers also used the furniture to explore the different furniture style options for placing custom orders. For many years, the order placed at the craft show supplied work for the next 12 months. George not only went to Springs festival but also displayed his crafts at the Dutch Family Festival in Lancaster, PA during the summer tourist season.

George engraved custom plaques ready in one hour. Other larger wood items like rockers, dry sinks, trestle table and benches were available for purchase. Customers also used the furniture to explore the different furniture style options for placing custom orders. For many years, the order placed at the craft show supplied work for the next 12 months. George not only went to Springs festival but also displayed his crafts at the Dutch Family Festival in Lancaster, PA during the summer tourist season. present a visual display of completed furniture. Larger furniture-dining room sets, bedroom suites, living room tables, entertainment centers are displayed.

present a visual display of completed furniture. Larger furniture-dining room sets, bedroom suites, living room tables, entertainment centers are displayed.

He referred to the cost and time difference of mass production assembly lines. We know many of our customers & guests wonder the same thing.

He referred to the cost and time difference of mass production assembly lines. We know many of our customers & guests wonder the same thing.

Furniture Experts

Furniture Experts Furniture designed, crafted, and assembled by master craftsmen endure the normal wear and tear of daily life. While George’s craftsmen are not Amish furniture makers, we are Master Craftsmen. George’s master craftsmen build each piece to suit the needs of the buyer now and in the future. Forever cherished assets.

Furniture designed, crafted, and assembled by master craftsmen endure the normal wear and tear of daily life. While George’s craftsmen are not Amish furniture makers, we are Master Craftsmen. George’s master craftsmen build each piece to suit the needs of the buyer now and in the future. Forever cherished assets. At George’s Furniture, one craftsman uniquely crafted each piece – signed and dated. 100% Pennsylvania hardwood construction—no plywood here! Each item is built-to-order, custom made to your specifications. Visit our showrooms and

At George’s Furniture, one craftsman uniquely crafted each piece – signed and dated. 100% Pennsylvania hardwood construction—no plywood here! Each item is built-to-order, custom made to your specifications. Visit our showrooms and