by Juanita | May 3, 2021 | Coffee End Table, customer experience, Customization, Events, George's Furniture, Hutch

George’s Difference – Viewing Your Own Handcrafted Furniture

The next time you visit Lancaster, PA we want to give you a tour of our shop where each piece of our solid wood furniture is handcrafted & custom made. Yes, it is true! We love bringing guests on a tour of our wood-working shop. Quite honestly, that is what makes us different from nearly any other furniture shop you can think of.

Of course, it is not just a tour of some automated wood shop. You see our craftsmen at work, literally drilling, planing, and staining with the tools in their hands to produce your perfect handcrafted solid wood furniture. Actually, we invite not only our guests but any customer with any order in progress to schedule a time to visit & watch their furniture crafted by hand right in front of their very eyes. That was how Tom & Karen found us!

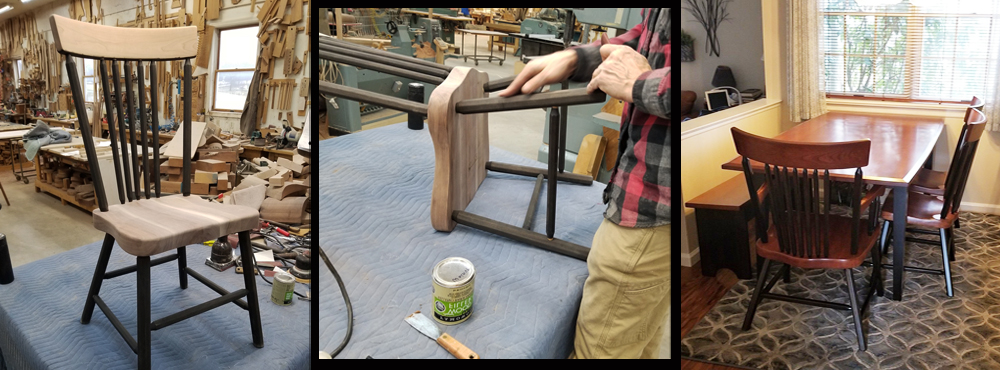

See furniture order handcrafted

“My wife and I had been furniture shopping for over a year and decided it was time to buy. While my wife was getting ready, I decided to make one last internet search for Lancaster County furniture stores. I was positive that we had already visited every furniture store so I was not optimistic about finding something new. George’s Furniture appeared on a list of stores we had previously visited, some of them multiple times. They were located near Maytown so I clicked on their website.” -Tom

The beauty of creating custom handmade furniture is that we can support your vision in a way that works for you, instead of just selling you assembly line, machine-made furniture.

Perhaps you need a dining table that is large enough to host all your children & grandchildren for a holiday meal. Maybe you are looking for a bedroom set that can become a family heirloom & add to the beauty of your home. In the professional setting, we even love designing executive desks & conference tables. (Did you know we even designed a conference table for the Pentagon?)

Beginning the handcrafted furniture process

“We were met by Anthony upon our arrival. After explaining what we were looking for, he expertly guided us through all the options. When ordering custom made furniture there are lots of decisions to make. After several hours our order was finalized.” -Tom

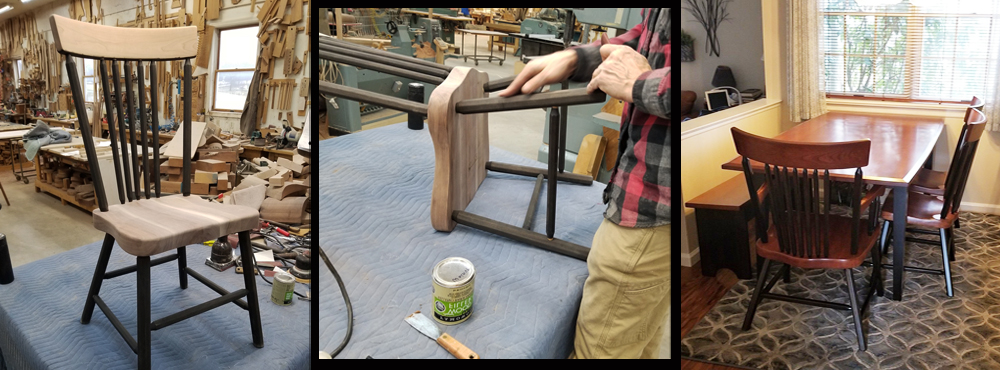

Tom and Karen worked with our designers to create the perfect dining set to meet their specific needs and interests. They also scheduled an appointment to see their furniture in process.

As we walked them through the tour, they saw the chairs ready for assembly. The artisan carefully placed glue into the precisely angled holes drilled into the seat for the chair legs. Tom and Karen observed the chair leveling process to make sure the chair would sit level in their home.

“I didn’t realize that so much work goes into making furniture.” — Tom

The finished table waited in the completed area. In the wood shop, they could see the other pieces of their set in progress too. A bench sat ready for assembly. The glued together coffee table wood top was ready for its next step of shaping and edge routing. The stained pantry waited for the final clear water-resistant coat of catalyzed conversion varnish.

Assembly lines vs handcrafted

Several minutes into the tour, Tom asked about the difference between George’s furniture process and other furniture manufacturing.

He referred to the cost and time difference of mass production assembly lines. We know many of our customers & guests wonder the same thing.

He referred to the cost and time difference of mass production assembly lines. We know many of our customers & guests wonder the same thing.

To be quite honest, mass production uses automated production lines and large sheets of plywood and particleboard in the construction. Since their focus is often on quantity over quality, they spend little time on matching grain or on preparing the wood well for assembly. We take the extra time of planing, cutting, and gluing the solid wood pieces together. That is what makes our process so different.

The path to quality

Handcrafted custom furniture made at George’s shop displays the careful attention to the wood grain, design, durability, and strength of the construction. Can I walk you through our complete process?

- Each artisan selects properly dried solid wood boards & cuts them to length. They use a jointer in their preparation process to make the boards flat, square & easy to assemble together (You can find out more about how jointers work here.) A thickness planer is also an essential part of this process to prepare the board & ensure that it is the same thickness all the way around the board. (The thickness planer is explained more here.)

- The furniture is ready for assembly after construction of all the individual parts. All those individual parts often include legs, skirts, tops, sides, solid wood drawers (fronts, sides, bottom), raised panel doors, rungs, seats, chair top, tongue-groove backing, etc.

- Next, they stain it and apply a clear coat of finish. The artisan signs and dates their finished piece before an all-over light sanding and final application of water-resistant clear coat of spray-top to bottom, inside and out. We actually asked our previous customers if they can still see the signature on their piece & these are the photos they shared with us.

- The final step in assembly is installing the hardware such as knobs & handles on drawers, adding in the table slides (our extension table is one of our most popular products actually!), and completing the tongue and groove backing.

- Last stop is the storage area where the finished product waits for the completion of the other pieces in the order. For example, maybe you have ordered a full dining table & chairs set like many of our other customers. Maybe you even ordered a bedroom suite of a bed, night stand & chest of drawers. This final waiting area is where we collect all pieces of an order before we deliver the complete set to the customer’s house.

Time to enjoy your gorgeous handcrafted furniture

“Our furniture was recently delivered and we are very happy with all the pieces. They are gorgeous and exactly as we ordered. The entire process from beginning to end was very pleasant and trouble free. We visited the shop and saw several of our pieces while in production. In closing, my wife and I would like to sincerely thank everyone at George’s Furniture.” – Tom & Karen

This is what makes us different from any other furniture shop you have visited. You set the vision & we are happy to share our catalog of creations if you need inspiration. Then you can tour our shop to watch our master woodworkers bring your vision to life. Finally you get to enjoy quality, handcrafted furniture that will last your family for decades.

To help you start this process to high quality, handcrafted furniture, we created this handy checklist to spot high-quality furniture. Download the checklist here so you know what to avoid in your furniture shopping. Then call us when you are ready to design your own custom, handcrafted piece.

by Juanita | Mar 20, 2021 | Ava Lee's History Corner, customer experience, George's Furniture, Rocking Chairs

Rocking chairs are cherished for their comfortable, gentle rocking ability that calms the nerves of a hard day. Mothers enjoy their newborn babies as they rock them to sleep. This is the story of how the Dubiel family discovered George’s Rocker Recliner.

Rocker’s Lost battle

Dick and Lori Dubiel purchased a rocking chair their home. An unfortunate experience happened to their rocker. Their uncle was rocking comfortably, when the rocking chair lost its battle and broke. Looking through the phone book, Lori found George’s Woodcrafts (presently George’s Furniture) and visited the store in Elizabethtown, PA, Lancaster County.

and visited the store in Elizabethtown, PA, Lancaster County.

Customer Remembers

“My uncle rocked in my not so great rocking chair and as he pushed on the arms to get up, they broke off. I had seen George’s store in Elizabethtown so I went in to ask if he could reattach the arms. As I looked at George’s quality of work, I realized that I did not want him to see my broken chair. Instead, I went and ordered one of his rockers to replace the broken rocker. I wanted a good quality chair that would survive my two boys and George’s non tipping rocker was perfect. I purchased a rocker that George had on the floor.” -Lori Dubiel.

Quality Discovered

As a result of Dick and Lori’s rocking experience, they discovered George’s  quality furniture. Their first furniture purchase was a walnut oval pedestal table set, dry sink and a crosscut stool. Once placing the order, the couple made small payments. However, as a surprise for his wife, Dick secretly placed additional money on their order. Lori’s mother joined into the fun and purchased her own rocking chair which she past unto her grandson. Five years later a corner hutch joined their collection.

quality furniture. Their first furniture purchase was a walnut oval pedestal table set, dry sink and a crosscut stool. Once placing the order, the couple made small payments. However, as a surprise for his wife, Dick secretly placed additional money on their order. Lori’s mother joined into the fun and purchased her own rocking chair which she past unto her grandson. Five years later a corner hutch joined their collection.

Individual Attention to Detail

George loved to delivery his own furniture. The Dubiel’s remember their corner hutch delivery. Once the hutch was carefully placed in their room, George proceeded to checked all his furniture to be sure that no damage occurred during the Dubiel’s recent move. Years later, the Dubiels moved to South Carolina but remain in contact through George’s monthly newsletter. Discover George’s solid wood furniture in Lancaster County PA today.

by Juanita | Dec 28, 2020 | Ava Lee's History Corner, customer experience, Customization, George's Furniture

David and Angela loved getting away from the stress of the office and the hustle and bustle of life in New Jersey. They enjoyed traveling to Lancaster County to the peace and tranquility of Amish and Mennonite farmland. Their favorite place to stay was the Cameron Estate Inn and Restaurant, Mount Joy, PA. The inn keepers, Abe and Betty Groff, were a delight to talk to which is the main reason why David and Angela’s return year after year.

Hand Engraved Road Signs

Traveling the Lancaster country roads, they often found hand-engraved road signs – George’s Woodcrafts- during their sight-seeing. David and Angela would pass by wooden signs thinking they did not need any birdhouses or small wood crafts. Finally one day they picked up an AAA travel guide and decided to check out George’s Woodcrafts. Were they surprised? George’s did not make birdhouses at all. Beautifully hand-crafted beds, dressers, long extension tables, smaller breakfast tables, tall tables were on display. Desks, bookcases, chairs, rocking chairs, benches, anything one could imagine greeted them-all specially designed to their special dimensions.

Small space challenge solved

Special dimensions were the challenge David and Angela faced. Their small house presented many problems for finding furniture that fit within the space. The search was over. They remember George Martin’s love for design and sharing of his unique designed rocker that did not tip over. He quickly pushed himself way back and it stopped. They could not forget this amazing design. Later a rocking chair found its way into their home. After sharing the history of the rocking chair, George proceeded to begin designing a small shelf that would mount to the side of the Finnegan’s bed.

Natural skill in designing

George’s did not need a picture of design from. He would listen to the customer’s needs and space requirements, then design and draw out a sketch of what was in his mind. David was embarrassed about how much time George devoted to them, designing their little bed side shelf, even this other customers around. The genuine desire to created and solve needs was why the Finnegan’s continued kept coming back for many more pieces of furniture over the years. Each room of their homes has at least one piece of furniture-except the bathroom.

George’s Legacy

Even though George has passed away, his daughter, son-in-law and skilled craftsmen carry the legacy of listening to customers’ needs and creating signed, dated, made by one craftsman, cherished hardwood heirlooms for over 50 years. Visit George’s showroom and see for yourself the Lancaster County quality of that drew David and Angela and captured their hearts.

by Juanita | Jun 22, 2020 | Ava Lee's History Corner, customer experience, Customization

Florida brothers experience George’s Furniture

George got a call late one Saturday afternoon near closing time. “Are you open on Sunday? We just found your brochure and are interested in seeing your furniture. Our return flight leaves for Florida on Monday morning.” replied the caller. “ I am very sorry, but we do not have hours open on Sunday. We would be happy to help you on Monday,” answered George Martin.

Flight changed

So they changed their flight and came into the showroom on Monday morning. A walk through the showroom and wood shop convinced them of our quality, but they wanted a different design for the head-board and foot-board of their king size bed. So George designed his first ocean wave bedroom suite. To the ocean wave poster bed, they added a dresser, vanity and nightstands.

Brother joins excitement

His brother heard about George’s quality furniture and wanted us to build a bookcase wall unit to encase a large fish aquarium. So he shipped the tank to us by freight to assure a perfect fit.

In the next few years, these brothers filled their homes with more furniture. One chose a roll top desk while the other got a computer desk with swivel desk chairs to match. The second brother chose a sleigh bed. A dresser, chest of drawers, night stands and a swivel full body mirror completed the set. Each one got entertainment centers and mantles for their fireplaces. One got an extension table, extra boards and chairs to accommodate guests when they come for dinner. Even their parents got in on the joy of handcrafted furniture, ordering a corner cupboard for their home.

Additional deliveries

We made several 16 hour trips to personally deliver their furniture over the next few years. On one trip, I was privileged to accompany George. I always enjoyed meeting our customers in their homes. After the furniture was safely moved into their homes, they gave us a tour of their massive vegetable fields. We enjoyed small plane aerial view over Lake Okeechobee and the Everglades, Florida.

This was a truly unforgettable experience with a wonderful family of George’s fans.

by Juanita | Feb 24, 2020 | 50th anniversary, Ava Lee's History Corner, Chair, Rocking Chairs

High Chair Designed

There is a saying, “Necessity is the mother of invention”. George and I spent our first year of marriage in the mountains of West Virginia. While there, I became pregnant with our first child. After spending a year there, we moved back to Elizabethtown, PA, Lancaster County in November 1969. George got a job at a saw mill where he learned about grades of hardwood lumber. In April our daughter, Juanita, was born. When she learned to sit up, George and I went shopping for a high chair. After a discouraging time of searching and not finding one that we liked, George said, “I think I will make one.” I looked at him in disbelief.

“I think I will make one.

“Oh yes, George”, I said, “I know that you can make things with wood, but a high chair with a tray? That seems quite complicated.” Well, I have learned not to question my husband when he says he will do something, because there isn’t much that he won’t try and with success. The high chair that he built has survived 4 children and is now in the historical museum section of the showroom. When we have family dinners that require 2 high chairs, the first high chair comes into my house to be used for one of my grandchildren.

Child’s High Chair legacy

After making the high chair, George made chairs for our table, replacing the folding chairs that we had received as a wedding gift. Soon after that, he designed:

- A rocking chair that will not tip over.

- Chairs of all sizes to go with the tables he was making,

- Arm chairs

- Intermediate chair for children ages 3-8.

- Swivel chairs for the bar

- Swivel desk chairs.

All chairs are made with a 2 inch plank bottom seat shaped for comfort, designed for strength. The eight sided rungs create extra strength and are inserted at precise angles, providing long lasting service.

“Necessity is the mother of invention”

It all began because our daughter needed a high chair. Come and explore the new ideas that were started by a unfulfilled need that Georges craftsmen listen and then created one-of-a-kind heirlooms that will serve for years to come. The wood shop and showrooms are located in the heart of Lancaster County’s farmland along the Susquehanna River. Enjoy the peaceful surroundings of nature as you create furniture that meets your need and brings nature’s beauty into the home.

He referred to the cost and time difference of mass production assembly lines. We know many of our customers & guests wonder the same thing.

He referred to the cost and time difference of mass production assembly lines. We know many of our customers & guests wonder the same thing.

and visited the store in

and visited the store in  quality furniture. Their first furniture purchase was a walnut oval pedestal table set, dry sink and a crosscut stool. Once placing the order, the couple made small payments. However, as a surprise for his wife, Dick secretly placed additional money on their order. Lori’s mother joined into the fun and purchased her own rocking chair which she past unto her grandson. Five years later a corner hutch joined their collection.

quality furniture. Their first furniture purchase was a walnut oval pedestal table set, dry sink and a crosscut stool. Once placing the order, the couple made small payments. However, as a surprise for his wife, Dick secretly placed additional money on their order. Lori’s mother joined into the fun and purchased her own rocking chair which she past unto her grandson. Five years later a corner hutch joined their collection.