by Juanita | Nov 29, 2024 | Ava Lee's History Corner, customer experience, Furniture Care, George's Furniture, Georges Difference, Tables

Solid hardwood will receive dents and scratches over the years of hard use. While the dents can be raised out (see instructions for minimizing dents), the accumulation over time may require refinishing – complete sanding and a new finish. Some people like those “memory marks” on their table while others want to see their old table new again. Not only are Georges Furniture tables protected with a durable water-resistant finish they can be refinished after years of hard use.

Refinished

After 18+ years of enjoying their Georges Furniture table, Rob and Melinda wanted to refinish their beloved table. They also loved the two-tone style, where we used two different stains or a combination of two different woods and stains. While we refinished their table we added a different stain to parts of the table for a two-tone look.

Word of Mouth

How did Rob and Melinda first find out about George’s quality handcrafted furniture. A different way. Yes, word of mouth is a great way to share the discovery of quality handcrafted furniture in Lancaster County, PA. One day a contractor who was doing work at a post office started a conversation with Rob, who drove a truck with the postal service. Rob shared his quest for quality furniture and the contractor said you must check out Georges Furniture in Marietta, PA near Maytown.

Narrow Table Search

Rob and Melinda searched around the furniture stores for a narrow table to fit in their space. 38-inch-wide table is not an easy size to find. They wanted to use some money that their mother gave to them. It is hard to find quality craftsmanship and custom sizes.

Love at first sight

The minute they walked into George’s showroom they knew this was what she was looking for in size and quality. To be able to customize everything was unheard of in normal furniture stores. Rob and Melinda spent hours looking over the many options and decided on a perfect size, wood, leg style and edge. She gets compliments on the long overhang on the ends of her table. This space is great for the ladies who like to cross their legs. The tabletop needed to be wide enough to fit a meat platter and two dinner plates yet still small enough to fit in their dining area.

High Lights

Melinda remembers what impressed her most about Georges Furniture.

- Strength Test – 13 People standing on top of an extension table.

- A table that kept on extending – up to 21 feet.

- Wood shop tour

- Top quality craftsmanship

- Attention to detail

During deliver the delivery man accidentally scratched the table with his watch and took it back to be repaired. Melinda questioned why the table even needed to go back.

Customer Service

“The customer service is top notch.” -Melinda.

From visiting the showroom and wood shop to exploring the details of furniture on the order. We design, build and deliver our furniture. The service exceeds expectations.

by Juanita | Aug 27, 2022 | Ava Lee's History Corner, Coffee End Table, customer experience, Forestry Management

Recently Carl and Chris Geeseman returned to our showroom after three decades of enjoying the furniture built by George. Like so many of our customers, they wanted to share the memories of George. The memories started back in the 1970’s. Carl worked for Highspire lumber yard. Lumber yard typically cut the trees in the forest and transport them to a sawmill. They are looking for straight long trees. A good veneer log needs to be clear of bark, metal, knots, and blemishes.

Forgotten hammer

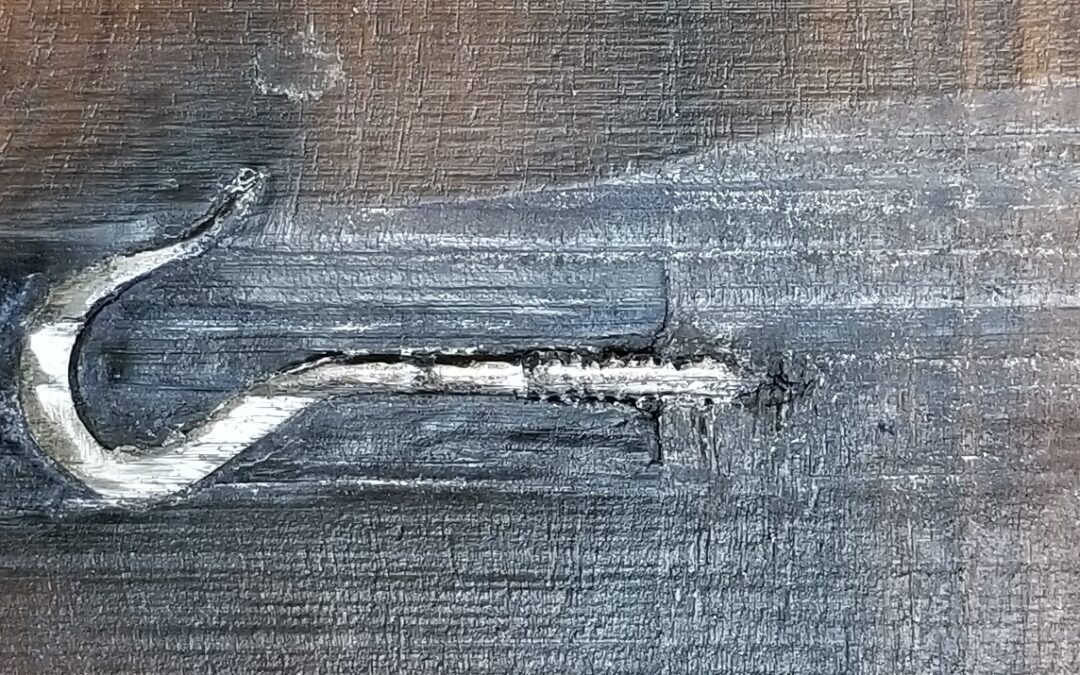

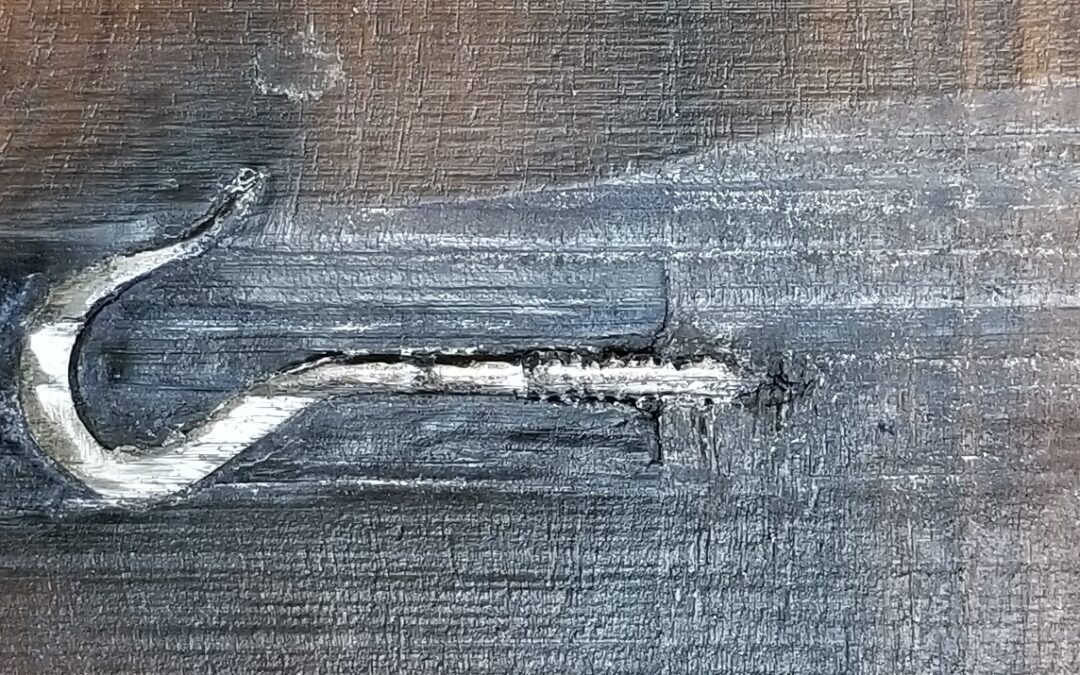

Metal is a big concern for logs that come from a residential area where metal hardware, bullets or even a forgotten metal screwdriver, hammer or animal trap discarded in the fork of a tree. Each year the tree grows a metal object will become embedded into the wood and unable to be withdrawn. The metal object will leave a scar and their minerals will seep into the wood. Not only does metal scar the wood it destroys.

Scars and destroys

Along comes a saw blade, cuts through the metal, or goes around the hook and the expensive blade loses its teeth or even destroyed. Metal can shut down a sawmill resulting a loss of time and money. Bandsaw blades are 12 feet long and 1 ft wide. They are razor thin and thousands of dollars. Lumber jacks look at the outside bark for marks or scars that shows healing from metal objects or use metal detectors to find metal. Think twice before hooking a wash line, swing, or sign to a tree. They are alive and growing.

George’s treasure pile

Highspire lumber piled their cut offs like bark, knots, rotten wood etc. aside and sold the straight boards to their customers. George loved to come and rummage through the cut off pile looking for unique knots, grain twists, chain saw wedges, rotten tree butts and odd shaped pieces of wood for his next project. Walnut and cherry were his favorite. Some cross cuts turned into coffee tables, end tables, Lamp bases, or even crosscut critters (a crosscut with a hole in the middle from where the hollow tree healed itself.)

Filling the House

Carl and Chris Geeseman started their furniture collection in 1980’s with a table set, dry sink and hutch. Next a bedroom set. Later as the family grew it was time for the kids’ room, a single bed, dresser and child’s play table and chairs. Then another bed, chest of drawers and nightstands. Next it was dad’s turn with a nice rolltop desk with finished back and swivel desk chair. As the family grew so did the table. Time to order more table leaves.

Resourceful Brothers

During family get togethers Carl and his brother would haul their table leaves to the other’s house. Since both brothers had tables from George’s, the table leaves fit together nicely. A curious situation happened. I discovered a leaf storage box with two different colored table leaves in our shop. The two brothers completed their 8-leaf table set by ordering 4 leaves each. Now the hassle of loading up the table leaves in the car was no longer needed. All 29 people crowd around the table and enjoy the comfort of family. A fun game the Geeseman children play is lining up the little child’s chairs and playing school bus.

Sharing the quality

That is not all the furniture in the Geeseman household. 2 high chairs served the growing family. Chris said that their kids sat in the high chairs so long until they no longer fit in between the arms. Chris stopped using the high chairs when she got tired explaining to the kid’s friends why the kids still sat in high chairs. The high chairs have endured 3 kids, and 5 grandchildren. Other items like rocking chairs (child and adult), quilt rack, cradle, Jewelry box, benches and round end table found their way into the home. There is room for more. Maybe a new bed.

Explore, Watch and Design

Join the Geeseman family and many customers over the 50+ years in their experience with Georges fine craftsmen and quality handcrafted furniture. Everyone worked with our designers to create the perfect piece that meets every need and endures hard use of family and friends. Begin creating your unique living space, designed, and built right in Lancaster County, PA. Explore ideas on our website, watch the wood shop in action (YouTube) and see what possibilities await discovery.

In the mean time, we have created this handy checklist on how to spot high-quality furniture. Down the checklist here so you know what to avoid in your furniture shopping. An informed mind will bring great results.

Download your Guide to High-Quality Furniture

by Juanita | Jun 2, 2022 | Ava Lee's History Corner, customer experience, Customization, George's Furniture, Tables

Our customers discover Georges Furniture by many different ways. Whether they find a brochure In Lancaster County, searched for quality furniture maker online, see the handmade furniture in a friend’s home or listened to the excited story of a satisfied customer, the furniture amazes them each time they enter the showrooms. What beautiful furniture, wonderful craftsmanship!

Explore handmade furniture

The Amsterdam family was no different. They came to see the wood shop tour and discovered the unique features of handcrafted, custom, and signed by one craftsman furniture all in one place. At the end of the tour they responded,

“Our house is full of furniture, however if we ever need furniture we know where we will come.”

Flooding Devastation

Two years after their visit, Hurricane Sandy hit the Eastern seaboard of the United. The family watched in terror as the water arose, filling the first floor and proceeded up the stairs to the next floor. Their furniture did not survive the flooding. Once the hurricane moved northward, the cleanup began.

Return to George’s

Once the clean up finished and their house ordered, it was time to look for furniture. As promised, the Amsterdam family came to the showroom with a unique request. “Will you help us fill our house with furniture?” I never thought I would be an interior designer, but they spread out the floor plan on our dining table and we proceeded through each room. First was the dining room then the master bedroom. I worked with each family member deciding the perfect design and options.

Which furniture to make first

Several hours later came the challenging part. Which room to make first. Dinning, master bedroom, teens bedroom, living room or den. Out of necessary, the dining table and chairs won along with the bedroom furniture. We updated each other as the house neared completion and ready for delivery.

Home restored

Over the next couple of years, we filled their house with custom handmade furniture designed to their desires. The furniture will serve the family for decades to come. Want to join in the discovery of quality craftsmanship, visit Georgesfurniturepa.com or visit our showroom and wood shop.

How to detect Quality

To help you start the process to high-quality, handcrafted furniture, we created this handy checklist to spot high-quality furniture. Download the checklist here so you know what to avoid in your furniture shopping. Then call us when you are ready to design your own customer, handcrafted piece.

Download you Guide to High-quality Furniture

by Juanita | May 3, 2021 | Coffee End Table, customer experience, Customization, Events, George's Furniture, Hutch

George’s Difference – Viewing Your Own Handcrafted Furniture

The next time you visit Lancaster, PA we want to give you a tour of our shop where each piece of our solid wood furniture is handcrafted & custom made. Yes, it is true! We love bringing guests on a tour of our wood-working shop. Quite honestly, that is what makes us different from nearly any other furniture shop you can think of.

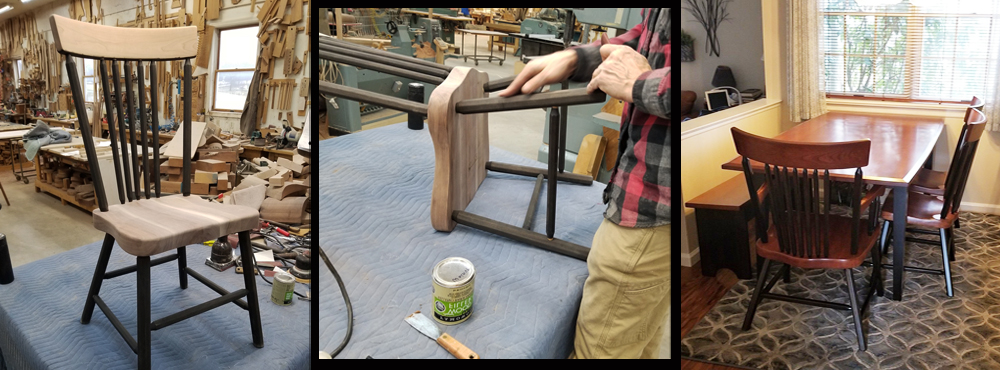

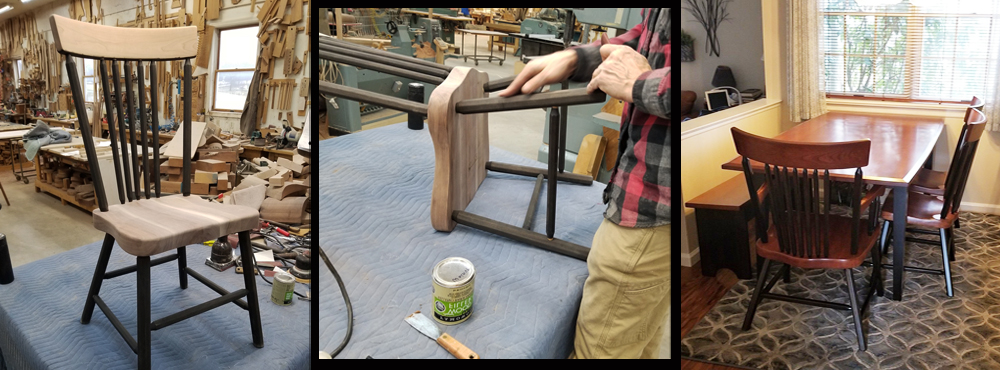

Of course, it is not just a tour of some automated wood shop. You see our craftsmen at work, literally drilling, planing, and staining with the tools in their hands to produce your perfect handcrafted solid wood furniture. Actually, we invite not only our guests but any customer with any order in progress to schedule a time to visit & watch their furniture crafted by hand right in front of their very eyes. That was how Tom & Karen found us!

See furniture order handcrafted

“My wife and I had been furniture shopping for over a year and decided it was time to buy. While my wife was getting ready, I decided to make one last internet search for Lancaster County furniture stores. I was positive that we had already visited every furniture store so I was not optimistic about finding something new. George’s Furniture appeared on a list of stores we had previously visited, some of them multiple times. They were located near Maytown so I clicked on their website.” -Tom

The beauty of creating custom handmade furniture is that we can support your vision in a way that works for you, instead of just selling you assembly line, machine-made furniture.

Perhaps you need a dining table that is large enough to host all your children & grandchildren for a holiday meal. Maybe you are looking for a bedroom set that can become a family heirloom & add to the beauty of your home. In the professional setting, we even love designing executive desks & conference tables. (Did you know we even designed a conference table for the Pentagon?)

Beginning the handcrafted furniture process

“We were met by Anthony upon our arrival. After explaining what we were looking for, he expertly guided us through all the options. When ordering custom made furniture there are lots of decisions to make. After several hours our order was finalized.” -Tom

Tom and Karen worked with our designers to create the perfect dining set to meet their specific needs and interests. They also scheduled an appointment to see their furniture in process.

As we walked them through the tour, they saw the chairs ready for assembly. The artisan carefully placed glue into the precisely angled holes drilled into the seat for the chair legs. Tom and Karen observed the chair leveling process to make sure the chair would sit level in their home.

“I didn’t realize that so much work goes into making furniture.” — Tom

The finished table waited in the completed area. In the wood shop, they could see the other pieces of their set in progress too. A bench sat ready for assembly. The glued together coffee table wood top was ready for its next step of shaping and edge routing. The stained pantry waited for the final clear water-resistant coat of catalyzed conversion varnish.

Assembly lines vs handcrafted

Several minutes into the tour, Tom asked about the difference between George’s furniture process and other furniture manufacturing.

He referred to the cost and time difference of mass production assembly lines. We know many of our customers & guests wonder the same thing.

He referred to the cost and time difference of mass production assembly lines. We know many of our customers & guests wonder the same thing.

To be quite honest, mass production uses automated production lines and large sheets of plywood and particleboard in the construction. Since their focus is often on quantity over quality, they spend little time on matching grain or on preparing the wood well for assembly. We take the extra time of planing, cutting, and gluing the solid wood pieces together. That is what makes our process so different.

The path to quality

Handcrafted custom furniture made at George’s shop displays the careful attention to the wood grain, design, durability, and strength of the construction. Can I walk you through our complete process?

- Each artisan selects properly dried solid wood boards & cuts them to length. They use a jointer in their preparation process to make the boards flat, square & easy to assemble together (You can find out more about how jointers work here.) A thickness planer is also an essential part of this process to prepare the board & ensure that it is the same thickness all the way around the board. (The thickness planer is explained more here.)

- The furniture is ready for assembly after construction of all the individual parts. All those individual parts often include legs, skirts, tops, sides, solid wood drawers (fronts, sides, bottom), raised panel doors, rungs, seats, chair top, tongue-groove backing, etc.

- Next, they stain it and apply a clear coat of finish. The artisan signs and dates their finished piece before an all-over light sanding and final application of water-resistant clear coat of spray-top to bottom, inside and out. We actually asked our previous customers if they can still see the signature on their piece & these are the photos they shared with us.

- The final step in assembly is installing the hardware such as knobs & handles on drawers, adding in the table slides (our extension table is one of our most popular products actually!), and completing the tongue and groove backing.

- Last stop is the storage area where the finished product waits for the completion of the other pieces in the order. For example, maybe you have ordered a full dining table & chairs set like many of our other customers. Maybe you even ordered a bedroom suite of a bed, night stand & chest of drawers. This final waiting area is where we collect all pieces of an order before we deliver the complete set to the customer’s house.

Time to enjoy your gorgeous handcrafted furniture

“Our furniture was recently delivered and we are very happy with all the pieces. They are gorgeous and exactly as we ordered. The entire process from beginning to end was very pleasant and trouble free. We visited the shop and saw several of our pieces while in production. In closing, my wife and I would like to sincerely thank everyone at George’s Furniture.” – Tom & Karen

This is what makes us different from any other furniture shop you have visited. You set the vision & we are happy to share our catalog of creations if you need inspiration. Then you can tour our shop to watch our master woodworkers bring your vision to life. Finally you get to enjoy quality, handcrafted furniture that will last your family for decades.

To help you start this process to high quality, handcrafted furniture, we created this handy checklist to spot high-quality furniture. Download the checklist here so you know what to avoid in your furniture shopping. Then call us when you are ready to design your own custom, handcrafted piece.

by Juanita | May 20, 2020 | Ava Lee's History Corner, customer experience, Customization, Entertainment Centers, George's Furniture

Does real wood furniture even exist anymore?

Meet Charles. He was seeking real wood furniture, an entertainment center, in fact, made of real wood that was high quality, not just a particle board & plywood piece. His search led him to many furniture stores & small businesses around Lancaster, York & Harrisburg. While our area includes many amazing small businesses (there is seriously so much to do here in Lancaster), Charles was having a hard time finding what he wanted. The majority of pieces he found lacked any hardwood elements. Instead he kept finding particle board & plywood pieces, the exact materials he wanted to avoid. If he was going to make a solid investment in his furniture, he wanted to know it would be durable, strong & resistant to warping or breakage.

Then Charles found George

While shopping at Meadow Brook Farmer’s Market in Leola, PA (which has since closed), Charles discovered George’s Woodcrafts storefront. After seeing our display of high quality, solid, hardwood furniture, he picked up a business card and called us. In fact, Charles came to visit our wood shop and showroom located near Maytown, PA, just a short drive from his home. At George’s, Anthony, one of our designers, greeted Charles and gave him a tour of the factory. Charles knew this was the place to get real wood furniture.

The Beauty of Real Wood Furniture Customized to You

Now, time to dive into the George’s Furniture process!

After discussing various dimensions and designs, Charles used his drafting ability to draw up detailed sketches of his entertainment center. Anthony took the sketches, verified the construction integrity and prepared an estimate for final approval by Charles.

Once Charles approved the final plans, one of our skilled craftsmen got to work! Each piece created by George’s Furniture is signed by the creator. You can actually see some signatures of our craftsman right here. Plus the beauty of custom wood furniture is that you, as the customer, can select the wood, stain & design you want. Charles loved the fact that he could choose 100% solid oak hardwood. Since all of the hardwood used at George’s Woodcrafts is native to PA, Charles knew he found the quality he was searching for.

Real Wood Furniture: no going back now

Truth be told, once Charles had that real hardwood entertainment center in his home, he knew he wouldn’t be satisfied with anything less than the George’s Furniture quality for all his future furniture purchases.

In fact, over the many years, Charles did indeed return to George’s to purchase many furniture pieces. Of course, each piece was custom designed & handcrafted according to his desires & specifications. (He is not the only customer who got hooked on George’s custom real wood furniture.) George Martin, our founder, even surprised Charles a time or two by making personal deliveries of the furniture.

Real Wood Furniture: high quality that lasts for years

The amazing thing about high quality real wood furniture is how long it lasts, and when you find the high quality craftsmen that we have at George’s, you just can’t help but bring every project to them. Thirteen years after Charles purchased the original entertainment center, he desired to add three doors to the front. He worked with Chris on the exact dimensions and stain color to match the original entertainment center. The new doors now complete the entertainment center, keeping dust out and components securely stored.

The ability to design and choose the details allowed Charles to create his dream living space. Furniture built with Pennsylvania solid hardwood, made in America and above all will last for decades: That is what we do at George’s Furniture. Order your own built-to-order, custom made to your specifications piece of George’s furniture. Start here with our guide to spotting high quality furniture. Then you can come and see right where your furniture is built or simply contact us.

He referred to the cost and time difference of mass production assembly lines. We know many of our customers & guests wonder the same thing.

He referred to the cost and time difference of mass production assembly lines. We know many of our customers & guests wonder the same thing.